U型磁力直线电机

描述

评论(1)

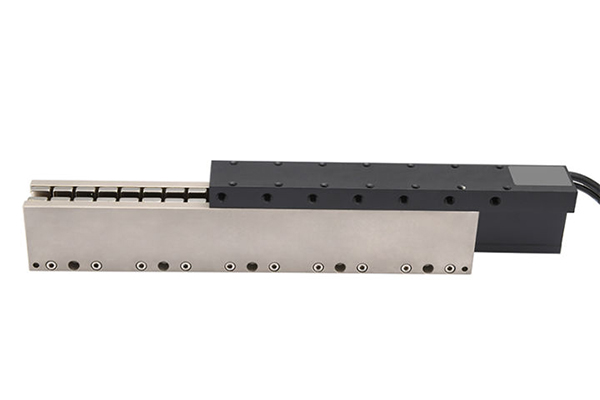

U型直线电机产品说明

线性电动机是一种电动机,其定子和转子“展开”,因此它不会产生扭矩(旋转),而是沿其长度产生线性力。然而,直线电机不一定是直的。特点是,直线电机的活动部分有端部,而更传统的电机布置为连续回路。

U 型同步直线电机的自由体图。U 型通道直线电机有两条平行的磁道,磁道彼此相对,磁板位于两板之间。驱动器由轴承系统支撑在磁轨中。施力器是无铁的,这意味着施力器和磁轨之间没有吸引力和干扰力。无铁芯线圈组件质量轻,可实现非常高的加速度。

通常,线圈绕组是三相的,采用无刷换向。通过为电机添加风冷可以提高性能,甚至还有水冷版本可供选择。这种设计更适合减少磁通量泄漏,因为磁铁彼此面对,安装在 U 形通道中。该设计还将强大的磁吸引力造成的伤害风险降至最低。

磁轨的设计允许将它们组合起来以增加行程长度,唯一限制操作长度的是电缆管理系统的长度;可用编码器长度;以及加工大型扁平结构的能力。

一、材料

磁铁:钕磁铁

硬件部分:20#钢,马氏体不锈钢

2.申请

“U 型”和“扁平”无刷直线伺服电机已被证明是机器人、执行器、工作台/平台、光纤/光子学对齐和定位、装配、机床、半导体设备、电子制造、视觉系统以及许多其他工业领域的理想选择自动化应用。

为什么选择直线电机?

1.动态性能

直线运动应用具有广泛的动态性能要求。根据系统的具体情况、占空比、峰值力和最大速度将决定电机的选择:

需要非常高的速度和加速度的轻负载应用通常会使用无铁芯直线电机(它的移动部件非常轻,不含铁)。由于它们没有吸引力,当速度稳定性必须低于 0.1% 时,首选带有空气轴承的无铁芯电机。

2、力速范围宽

直接驱动线性运动在很宽的速度范围内提供高力,从失速或低速条件到高速。由于技术受到涡流损耗的限制,直线运动可以实现非常高的速度(高达 15 m/s),但需要权衡铁芯电机的力量。

直线电机实现了非常平滑的速度调节,纹波低。直线电机在其速度范围内的性能可以在相应数据表中的力-速度曲线中看到。

3. 易于集成

磁铁直线运动有多种尺寸可供选择,并且可以轻松适应大多数应用。

4. 降低拥有成本

有效载荷与电机运动部件的直接耦合消除了对机械传动元件(如丝杠、同步带、齿条和小齿轮以及蜗轮驱动)的需求。与有刷电机不同,直接驱动系统中的运动部件之间没有接触。因此,没有机械磨损,从而具有出色的可靠性和较长的使用寿命。更少的机械部件最大限度地减少维护并降低系统成本。